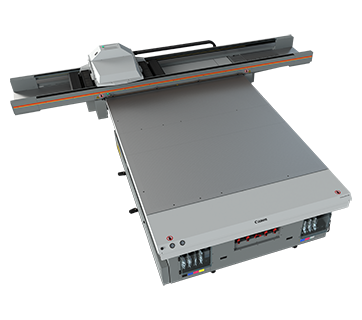

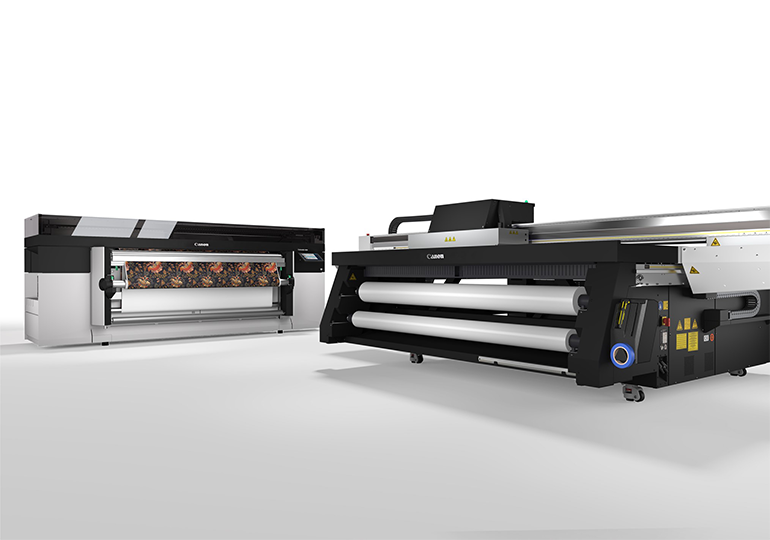

Rigid productivity by design

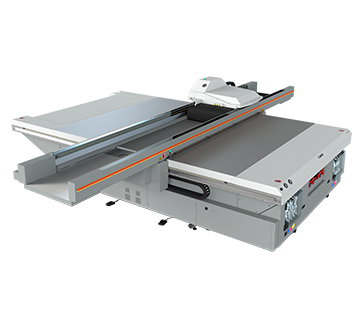

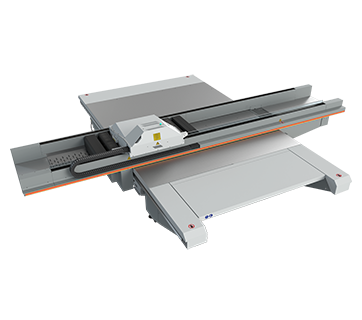

Arizona 6100-Series dedicated high volume flatbed systems are ideal for sign and display graphics print service providers with a production potential in excess of 30,000m2 per year.

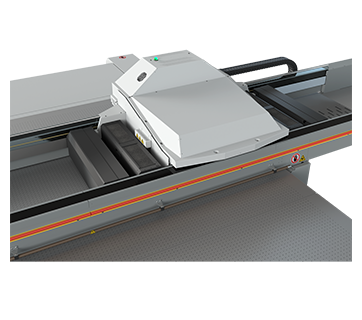

Designed as a productivity platform, the Arizona 6100-Series delivers fast, reliable and high quality inkjet print production at up to 155m2 per hour. An extra-large, dual origin flatbed table with two independent vacuum zones allows for non-stop production of standard size 1.25 x 2.5m boards with simultaneous printing and media loading/unloading.